Each new generation of NAND flash memory reduces the fabrication geometry the dimension of the smallest part of an integrated circuit used to build up the components inside the chip. That means there are fewer electrons storing the data, leading to increased errors and a shorter life for the flash memory. No need to worry. Today’s flash memory depends upon the intelligence and capabilities of the solid state drive (SSD) controller to help keep errors in check and get the longest life possible from flash memory, making it usable in compute environments like laptop computers and enterprise datacenters.

Today’s volume NAND flash memory uses a 20nm and 19nm manufacturing process, but the next generation will be in the 16nm range. Some experts speculate that today’s controllers will struggle to work with this next generation of flash memory to support the high number of write cycles required in datacenters. Also, the current multi-level cell (MLC) flash memory is transitioning to triple-level cell (TLC), which has an even shorter life expectancy and higher error rates.

Can sub-20nm flash survive in the datacenter?

Yes, but it will take a flash memory controller with smarts the industry has never seen before. How intelligent? Sub-20nm flash will need to stretch the life of the flash memory beyond the flash manufacturers specifications and correct far more errors than ever before, while still maintaining high throughput and very low latency. And to protect against periodic error correction algorithm failures, the flash will need some kind of redundancy (backup) of the data inside the SSD itself.

When will such a controller materialize?

Now.

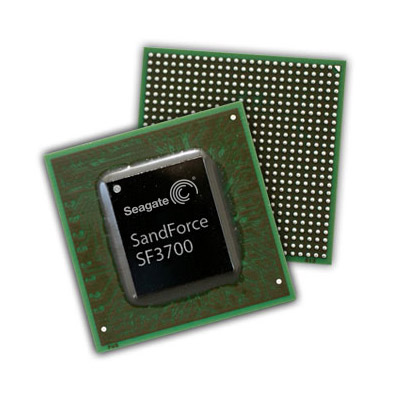

November 2013 marked the introduction of Seagate’s third generation SSD and flash memory controller, called the SandForce SF3700. The controller is newly engineered and architected to solve the lifespan, performance, and reliability challenges of deploying sub-20nm flash memory in today’s performance-hungry enterprise datacenters. The SandForce SF3700 also enables longer periods between battery recharges for power-sipping client laptop and ultrabook systems. It all happens in a single ASIC package. The SandForce SF3700 is the first SSD controller to include both PCIe and SATA host interfaces natively in one chip to give customers of SSD manufacturers an easy migration path as more of them move to the faster PCIe host interface.

How does the SandForce SF3700 controller make sub-20nm flash excel in the datacenter?

Our new controller builds on the award-winning capabilities of the current SandForce SSD and flash controllers. We’ve refined our DuraWrite data reduction technology to streamline the way it picks blocks, collects garbage and reduces the write count. You’ll like the result: longer flash endurance and higher read and write speeds.

The SandForce SF3700 includes SHIELD error correction, which applies LDPC and DSP technology in unique ways to correct the higher error rates from the new generations of flash memory. SHIELD technology uses a multi-level error correction schema to optimize the time to get the correct data. Also, with its exclusive Adaptive Code Rate feature, SHIELD leverages DuraWrite technology’s ability to span internal NAND flash boundaries between the user data space and the flash manufacturers dedicated ECC field. Other controllers only use one size of ECC code rate for flash memory the one largest size designed to support the end of the flash’s life. Early in the flash life, a much smaller size ECC is required, and SHIELD technology scales down the ECC accordingly, diverting the remaining free space as additional over provisioning. SHIELD partially increases the ECC size over time as the flash ages to correct the increasing failures, but does not use the largest ECC size until the flash is nearly at the end of its life.

Why is this good? Greater over provisioning over the life of the SSD improves performance and increases the endurance. SHIELD also allows the ECC field to grow even larger after it reaches its specified end of life. The big takeaway: All of these SHIELD capabilities increase flash write endurance many times beyond the manufacturers specification. In fact at the 2013 Flash Memory Summit exposition in Santa Clara, CA, SHIELD was shown to extend the endurance of a particular Micron NAND flash by nearly six times.

That’s not all. The SandForce SF3700 controller’s RAISE data reliability feature now offers stronger protection, including full die failure and more options for protecting data on SSDs with low (e.g., 32GB & 64GB) and binary (256GB vs. 240GB) capacities.

So what about end user systems?

The beauty of all SandForce flash and SSD controllers is its onboard firmware, which takes the one common hardware component the ASIC and adapts it to the users storage environment. For example, in client applications the firmware helps the controller preserve SSD power to enable users of laptop and ultrabook systems to remain unplugged longer between battery recharges. In contrast, enterprise environments require the highest possible performance and lowest latency. This higher performance draws more power, a tradeoff the enterprise is willing to make for the fastest time-to-data. The firmware makes other similar tradeoffs based on which storage environment it is serving.

Although most people consider the enterprise and client storage needs are very diverse, we think the new SandForce SF3700 Flash and SSD controller showcases the perfect balance of power and performance that any user hanging ten can appreciate.

Leave A Comment