It’s not only about whether a drive will break

A conversation with Rich Segar, Seagate’s senior director of Reliability Engineering

Rich Segar, senior director of Reliability Engineering at Seagate

Seagate’s craftspeople obsess over quality. Each of our data management and storage solutions undergoes over 160 unique quality assurance tests from the initial concept through the development life cycle. Check out this interview — Seagate senior editor Agnieszka Zielinska sat down with Rich Segar, senior director of Reliability Engineering at Seagate, to find out why and how we fuss over reliability. Watch the video below to see some of our test chambers, and visit our Quality Assurance story for a peek inside Seagate’s rigorous quality and reliability processes.

Why is quality important?

Quality assurance has many different facets, but at Seagate our customer experience is one of our top metrics. Providing a product that consistently meets the expectations of the customer is key to building trust and confidence. And relationships are the door to further business opportunities for Seagate.

How do we go about quality assurance at Seagate?

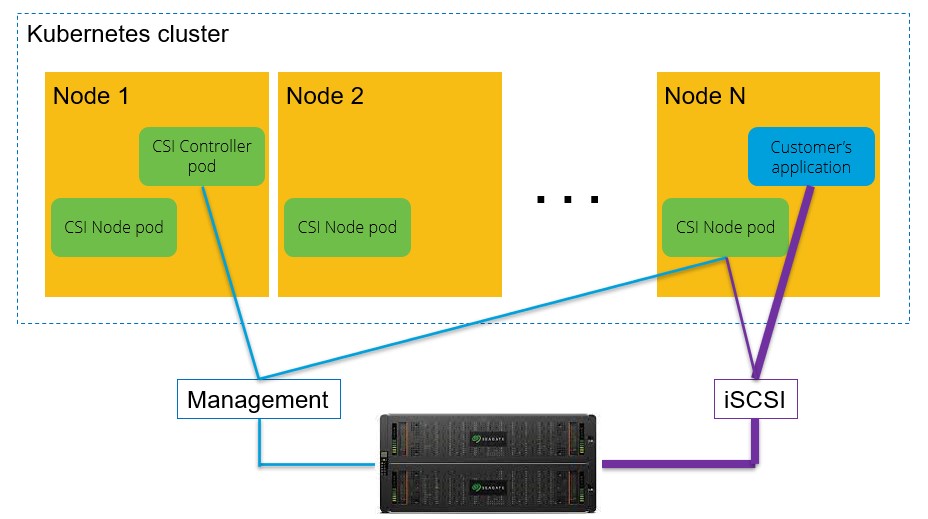

Understanding the customers’ expectations and their environments—temperature, humidity, workloads, failure criteria, and other factors—is central to the reliability of the products we ship. Our job is to understand the customer’s applications, use cases, critical requirements, and the impact of our quality on their business. It’s Seagate’s job to deploy these insights into our internal drive requirements so we can deliver to them what they need—solutions that will run flawlessly at different temperatures and workloads providing customers with reliability and availability of data.

Are you saying the “quality” story is really the “customer-first” story?

Yes. It has to be, because then customers can count on us and, in turn, want us to be successful. When they want us to be there for them, it makes everything about being a producer easier—not to mention more profitable.

What’s the driving question of quality assurance?

The question for us at Seagate about quality is not: “Is this drive going to break?” Quality is not only about whether the drive will break or not; that’s just a start. Quality is about whether the brand can build trust with its customers. It’s about the total customer experience. Is the install base performing as expected? How are the customers being serviced in the field? How are they being helped by the sales team? By pricing negotiations? On repairs? On technology? It’s the entire picture that builds trust. That being said, it’s a given that we do everything we can, through design and manufacturing excellence, to prevent product failures in the field. But that kind of device-level quality provides the foundation to service higher-order needs.

How has quality assurance changed at Seagate during your tenure?

Since I started this job in 2012, Seagate has completely shifted its mindset to focus on delivering to the customer quality expectations and putting the customer first. We’ve shifted from a company often trying to cost-justify each individual quality decision, to a company that focuses on satisfying customers as the central and vital priority which enables revenue for the long-term.

Quality is not only about whether the drive will break or not; that’s just a start. Quality is about whether the brand can build trust with its customers. It’s about the total customer experience. How are the customers being serviced in the field? How are they being helped by the sales team? By pricing negotiations? On repairs? On technology? It’s the entire picture that builds trust.

Can you give an example of quality at work?

Within the Industry 4.0 context—the fourth wave of industrial revolution and its expression as IT 4.0 in our world—the concept is to have automated data infrastructure, where we can benefit from real-time connectivity from customers through to design, supply chain, and the factory. Seagate invested in advanced analytics capabilities across multiple organizations to bridge the connected, real-time IT 4.0 infrastructure and create models to predict product quality and optimize reliability. These models are being used during design, and on the factory floor, to make real-time decisions and optimally deliver on customer requirements.

Test ovens in a Seagate reliability lab

Does this IT 4.0 evolution mean Seagate’s factories can take advantage of AI or deep learning and advanced analytics, in order to detect and correct anomalies or otherwise improve efficiency?

Yes, that’s a big part of it. Seagate has an entire big data infrastructure deployed where we are using telemetry and fleet management to pull information from customers to enhance customer support, and link data to design center data, factory data and supplier data to optimize decisions. Seagate deploys end-to-end analytics. In this context, IT 4.0 is about being able to link all ends of your infrastructure with data, in order to make real-time data-based decisions, and benefit the customer.

Aside from quality assurance in our manufacturing, how else is the IT 4.0 ecosystem helping our customers?

IT 4.0 enables us to monitor the performance of our drives in customer systems, in real-time. This information is used to give them direction on how to optimize our drives in their field environment and, as a result, how they can obtain a lower total cost of ownership. We’re intent on optimizing our quality and reliability around customers’ use cases in order to better target our requirements for their applications. This, in turn, allows us to optimize efficiency in our operations.

Environmental test chambers help ensure drives run flawlessly under different conditions and workloads.